Home |

Technologien & Produkte |

Aktives hydromechanisches Tiefziehen

Technologiefelder zu diesem Produkt

Kostenersparnis durch aktives hydromechanisches Tiefziehen

Beschreibung

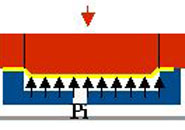

Das Verfahren unterscheidet sich vom hydromechanischen Tiefziehen dadurch, dass das Blech zuerst entgegen der Stempelbewegungsrichtung vorgebeult wird, bevor der Stempel ins Blech eintaucht. Dabei erhält das Bauteil eine Kaltverfestigung, die sonst mit konventionellem Tiefziehen im Mittenbereich des Bauteils schwer erreichbar wäre. Außerdem wird – wie auch beim hydromechanischen Tiefziehen – ein im Vergleich zum konventionellen Tiefziehen größeres Ziehverhältnis erreicht sowie eine Werkzeughälfte eingespart.Da die Taktzeit höher als beim hydraulischen Tiefziehen ist, ergibt sich in der Regel bei kleineren und mittleren Stückzahlen eine Kostenersparnis.

Ansicht

Schematische Darstellung des aktiven hydromechanischen Tiefziehens (1)

Schematische Darstellung des aktiven hydromechanischen Tiefziehens (1)

Schematische Darstellung des aktiven hydromechanischen Tiefziehens (2)

Schematische Darstellung des aktiven hydromechanischen Tiefziehens (2)

Kontakt