Home |

Technologien & Produkte |

Machbarkeitsanalyse und Simulation

Branchen zu diesem Produkt

Technologiefelder zu diesem Produkt

Effektive Simulation durch Finite-Elemente-Methode

Beschreibung

Als Hilfsmittel bei der Bauteilentwicklung sowie für die Bestätigung eines bei der Machbarkeitsanalyse ermittelten Fertigungskonzeptes wird die Umformsimulation mittels Finite-Elemente-Methode (FEM) hinzugezogen. Mit dieser Simulation wird der IHU-Prozess einschließlich eventuell vorgelagerter Umformprozesse wie Vorbiegen, Reduzieren, Vorformen realitätsnah abgebildet. Dadurch lässt sich schon im Vorfeld erkennen, ob ein Bauteil realisierbar ist oder ob Modifikationen erforderlich sind.Die darauf folgende Werkzeugkonstruktion wird von einer linearen FEM-Simulation begleitet. Diese Simulation dient der Feststellung der Spannungsverteilung, der Verformung sowie der Lokalisierung von Spannungsspitzen im Werkzeug. So kann der Start in den Werkzeugbau und das folgende Prototyping mit einem optimierten Bauteil und einem durch die FEM abgesicherten Werkzeug erfolgen.

Ansicht

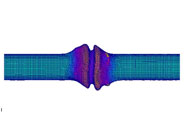

Bauteilversagen durch Faltenbildung in der ersten Simulationsschleife

Bauteilversagen durch Faltenbildung in der ersten Simulationsschleife

Am Ende des Optimierungsprozesses steht das fertige IHU-Bauteil.

Am Ende des Optimierungsprozesses steht das fertige IHU-Bauteil.

Downloads

Leichtbautechnologien von Schuler (3.44 MB)

Kontakt